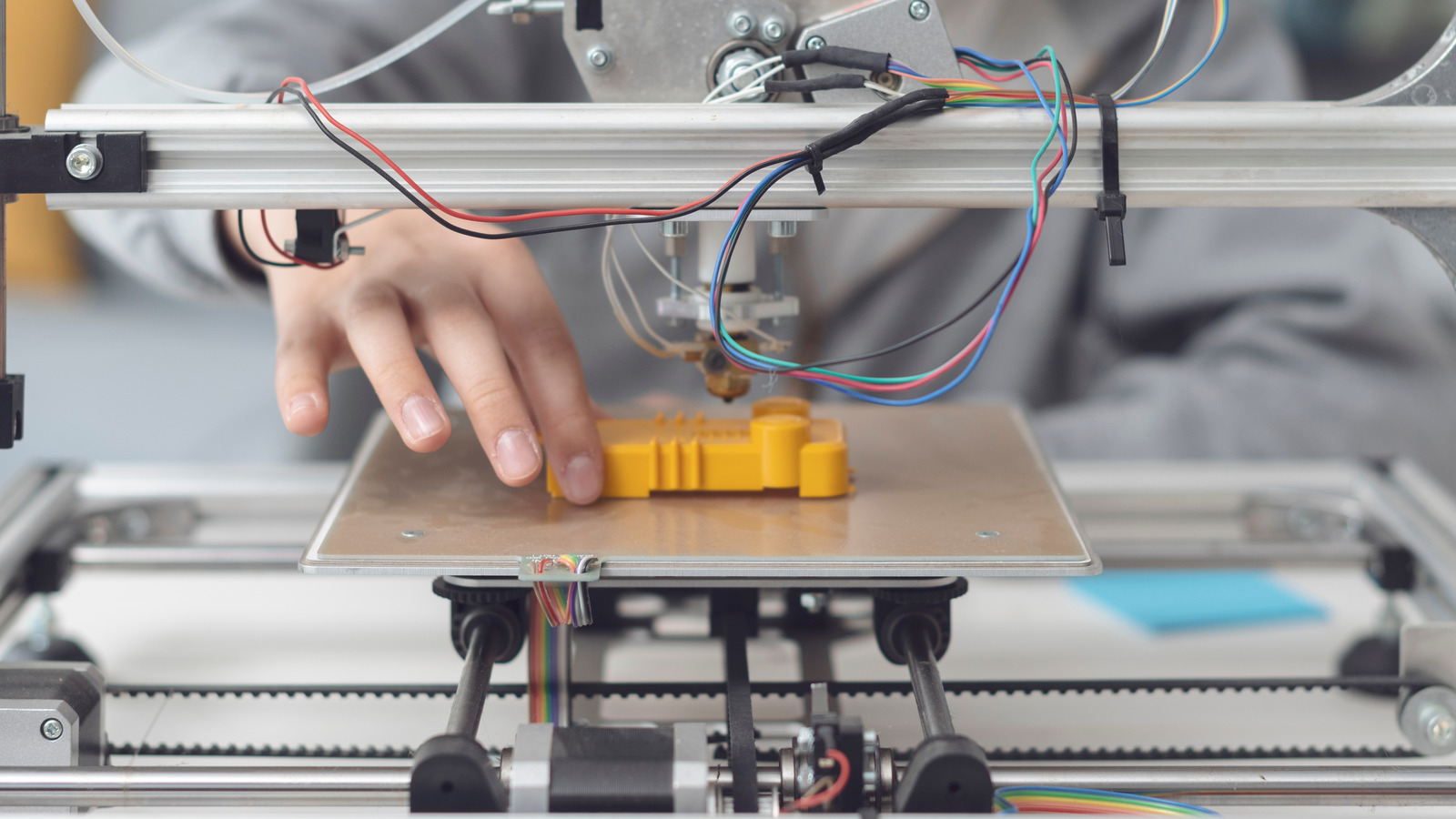

The printing process of a 3D printer operates on the assumption that the space above the bed is completely identical to how the computer needs it to be, so when it isn’t, things get thrown out of whack. It’s your job to keep the bed of the printer completely leveled out. To clarify, we don’t mean the device itself, as the bed is maintained independently of the overall printer. Rather, you need to ensure that the nozzle can move to and from all points of the printer bed without rattling or destabilizing. Most 3D printers come with a calibration routine you can run to check this, moving the nozzle to a zero point before bringing it all around the bed. Just make sure you heat the nozzle up first. Hot metal moves differently than cold metal, after all.

As the printer nozzle dispenses plastic in the specified shape, it is important that the plastic stays exactly where it was placed. You can’t very well print in 3D if your plastic is collapsing into a 2D pile of mush. To facilitate the proper printing environment, you need to ensure that the bed is not only cleaned of potential contaminants but also subtly sticky enough to hold everything in place. After every print, you should clean the bed with a paper towel wetted with 91% isopropyl alcohol. That kind is usually used as a first-aid antiseptic and can be purchased at your local pharmacy or supermarket. This process will prevent the buildup of plastic residue on the bed, which can mess with the surface. If you’re having trouble restoring the bed’s subtle stickiness, you can give it a very light brushing with a washable glue stick.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Entertainment News Click Here