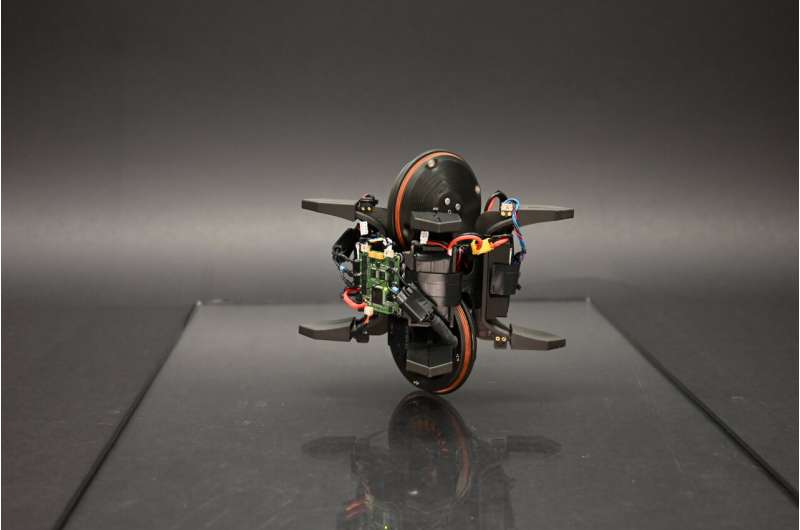

Researchers at RWTH Aachen University in the team of Prof. Sebastian Trimpe and the Max Planck Institute for Intelligent Systems (MPI-IS) Stuttgart have recently developed the Wheelbot a symmetric reaction wheel unicycle that can autonomously jump onto its wheels from any initial position. This unique robot, introduced in a paper published in the IEEE Robotics and Automation Letters was fabricated using a combination of off-the-shelf and 3D printed components.

“Our research group works at the intersection between data science and engineering. One particular direction of our research focuses on combining insights from control theory with machine learning,” René Geist, member in Trimpe’s team in Aachen and lead researcher behind the Wheelbot, told Tech Xplore. “Testbeds such as pendulums, robot arms, and quadcopters, help us to check if the theoretical assumptions underlying an algorithm are practical in reality. Ideally, these testbeds are simple to use while being challenging to control with state-of-the-art algorithms, forcing us to think outside the box.”

Two other examples of such testbeds are the so-called “Balancing Cube” and its descendant the “Cubli”. These two systems have often helped to evaluate the effectiveness of network control systems and data-driven methods for achieving non-linear control.

The recent work by Trimpe, Geist and their colleagues builds on these previous efforts in the field. Their goal was to develop a minimalistic unicycle robot that could be used as a testbed by roboticists and computer scientists worldwide. To do this, Trimpe and his research group at RWTH Aachen University joined forces with Jonathan Fiene, head of the ZWE Robotics laboratory at the MPI-IS.

“Early on in the project, we opted for using brushless motors, as the ZWE robotics has plenty of experience using these in the open dynamic robot initiative, while prices for light-weight brushless motors dropped due to the widespread adaption of quadcopters in the consumer market,” Geist explained. “When you look at a motor, arguably the simplest actuator one can come up with is to attach a wheel to it. If such a wheel touches the ground, we call it a ‘rolling wheel’, if it does not, we refer to it as a ‘reaction wheel’.”

Balancing a single-body, non-flying robot with the ability to drive and perform maneuvers generally requires a minimum of two wheels. These can either be rolling wheels, resulting in a Segway-like robot or a single rolling wheel and a reaction wheel, resulting in what is known as a “reaction wheel”—or “moment exchange’—unicycle robot.

Unicycle robots integrating reaction wheels have very simple designs and can easily be assembled by both expert roboticists and students. Despite their simplicity, reaction wheel unicycles are quite difficult to control. This makes them particularly favorable testbeds for research on robot networks and learning-based control methods.

“Previously proposed unicycle robots are designed to solely balance closely around their upright equilibrium position which considerably limits what you can do with these systems,” Geist said. “To maximize the utility of a reaction wheel unicycle robot, we decided that the Wheelbot must be able to recover from rather large disturbances, has an onboard power supply to prevent cables limiting its maneuverability, and in addition must be able to self-erect after toppling.”

Like the wheels of unicycles, the Wheelbot has a rolling wheel that prevents it from toppling while moving longitudinally. In contrast with unicycles, however, the robot also integrates a reaction wheel that prevents it from toppling in the lateral direction.

“To grasp the inner workings of a reaction wheel, you can do a simple experiment at home,” Geist said. “All you need is a swivel chair and a moderately heavy object, such as a cat. Sit with your knees on the chair and straighten your arms while holding the cat, then rotate your upper body clockwise. While the cat succumbs to its fate, you will notice that your knees rotate anti-clockwise. In this analogy, your upper body denotes the motor’s rotor while your lower body denotes the motor’s stator.”

Essentially, in reaction wheels, when a motor’s rotor (attached to the wheel) rotates clockwise, the motor’s stator (attached to the rest of the Wheelbot) will rotate anti-clockwise. Robots that balance using a reaction wheel differ from robots that resort to gyroscopes for balancing. In a gyroscope, a fast-spinning wheel is rotated orthogonally in relation to its direction of rotation creating balancing torques due to a conservation of angular momentum.

In a reaction wheel these effects also occur, but are miniscule compared to the reaction torques. Reaction torques are created directly inside the wheel and point parallel to the wheel’s direction of rotation.

“During self-erection, reaction torques must rotate the Wheelbot by 90 degrees,” Geist explained. “During the maneuver, the Wheelbot’s motor draws 16 Ampere at 24 Volts. For a 22 cm (8.7 inch) large robot, the motors actually pack quite a punch, forcing us to use a custom designed motor controller, as commercially available motor controllers were either too big or could not handle enough current at the given voltage.”

At a current draw of 16 Ampere, the researchers found that the motor moving the Wheelbot reached its rate limit in just 0.25 seconds. Due to this limitation and other challenges typically encountered when building reaction wheel-based unicycles, Geist and his colleagues decided to devise an entirely new design for their robot.

“First, we decided that the robot should be symmetric, effectively reducing the number of different parts that one needs to print and allowing the Wheelbot to use any of its wheels as rolling wheel,” Geist said. “Symmetry has the additional advantage that the upper wheel must be considerably smaller compared to existing unicycle robots which reduces its rotational inertia in yaw direction. Second, we designed the robot’s dimensions to minimize the required torque for self-erection.”

In initial tests, the researchers found that the standard version of their robot could jump onto its wheels from any initial positions in two steps. This allows the robot to decelerate its reaction wheel before completing the second and final step (i.e., pushing itself back up). ‘

In addition to creating a prototype of their robot, Geist and his colleagues also created a customized state estimator, an algorithm that can estimate the robot’s roll and pitch angles. This system derives its estimations from measurements of the robot’s four inertial measurement units (IMUs) and wheel encoders, which are only based on prior and available knowledge about the robot’s so-called kinematic model (i.e., a mathematical description of the position of the robot’s center of mass).

“We think that in the case of wheeled robots (including Ballbots), the proposed estimator forms an interesting alternative to other estimation algorithms such as Kalman filtering,” Geist said. “The Wheelbot demonstrates that a concise choice of a reaction wheel unicycle robot’s dimensions and hardware yields a versatile testbed for robotics control.”

Geist and his colleagues were the first to create a unicycle robot that can efficiently jump on its wheels from any initial position. Their paper is thus an important contribution to the field of robotics, as it solves the electronic and mechanical challenges typically encountered when creating this new type of reaction wheel-based unicycles.

“Besides being a challenging testbed for robot control, we see big potential for the Wheelbot as an educational platform introducing students to robotics,” Geist said. “In this regard, the Wheelbot is a typical example for demonstrating the interdisciplinary nature of robotics. Besides its mechanical design requiring modeling and simulating the robot’s quite interesting dynamics, the high-current draw of its motors pose significant challenges on its electronics design.”

In the future, the Wheelbot could be used in both educational and research settings to test robotic control networks, machine learning algorithms and other models. A key advantage of the robot is that its operation only requires a basic knowledge of software engineering, which makes it an ideal experimental platform for students and engineers making their first steps in robotics.

Researchers in Trimpe’s team are now working on a new version of their robot, called Wheelbot v3. A core goal is to make the robot even more accessible, so that is easier to build, use, and experiment with.

“The next version of the Wheelbot will be a bit smaller than the current version, uses a more powerful microcontroller, and in term of its firmware design is easier to operate,” Geist added. “In addition, we currently work on a control algorithm that steers the Wheelbot along a predefined path. After building the first jumping reaction wheel unicycle robot, we are excited to demonstrate that the Wheelbot is also able to perform agile driving maneuvers.”

A wheeled car, quadruped and humanoid robot: Swiss-Mile Robot from ETH Zurich

A. Rene Geist et al, The Wheelbot: A Jumping Reaction Wheel Unicycle, IEEE Robotics and Automation Letters (2022). DOI: 10.1109/LRA.2022.3192654

© 2022 Science X Network

Citation:

The Wheelbot: A symmetric unicycle with jumping reaction wheels (2022, August 15)

retrieved 15 August 2022

from https://techxplore.com/news/2022-08-wheelbot-symmetric-unicycle-reaction-wheels.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here